2026 How to Choose the Right Box Wrapper Machine for Your Business?

Choosing the right box wrapper machine for your business can be challenging. There are various types available. Each one comes with unique features and benefits. Understanding your specific needs is essential.

Consider your production volume. A high-output machine may be necessary for larger companies. For smaller operations, a cost-effective model might suffice. Think about the types of products you package. Some machines work better with specific shapes or sizes.

Budget is another crucial factor. A high-end box wrapper machine can be expensive. However, lower-priced models might lack essential features. Do your research and weigh the pros and cons. Reflect on what will serve your business best in the long run. Ultimately, the right choice can enhance efficiency and reduce costs.

Understanding the Different Types of Box Wrapper Machines Available

When selecting a box wrapper machine, understanding the different types available is crucial. These machines vary significantly in design and functionality. Most commonly, you'll find automatic and semi-automatic models on the market. According to industry reports, the global packaging machinery market is projected to reach over $40 billion by 2027, indicating the rising demand for efficient packaging solutions.

Semi-automatic machines require manual intervention, offering flexibility for small to medium-sized businesses. They are often less expensive, making them an attractive option. However, these machines may slow down production during peak times. On the other hand, automatic box wrapper machines deliver high-speed wrapping. They are ideal for large-scale operations but come with a higher price tag and maintenance costs. Choosing the right machine depends on your production needs and budget constraints.

Tips: Consider the volume of products you package daily. If you foresee growth, investing in an automatic model may save costs in the long run. Evaluate your facility's space, as some machines require extensive room for operation. Additionally, ensure you understand the learning curve associated with each machine. Not all staff may find it easy to operate complex systems. It's essential to assess training needs as well.

2026 How to Choose the Right Box Wrapper Machine for Your Business?

| Machine Type | Wrapper Type | Speed (Boxes/Min) | Ideal for | Price Range ($) |

|---|---|---|---|---|

| Semi-Automatic Wrapper | Film Wrapper | 15-20 | Small to Medium Businesses | $5,000 - $10,000 |

| Fully Automatic Wrapper | Shrink Wrapper | 30-50 | Large Scale Operations | $15,000 - $25,000 |

| Horizontal Wrapper | Plastic Wrapper | 25-35 | Food and Beverage Industry | $10,000 - $20,000 |

| Top Load Wrapper | Paper Wrapper | 20-30 | Consumer Goods | $8,000 - $15,000 |

| Case Wrapper | Cold Wrap | 40-60 | Distribution Centers | $20,000 - $30,000 |

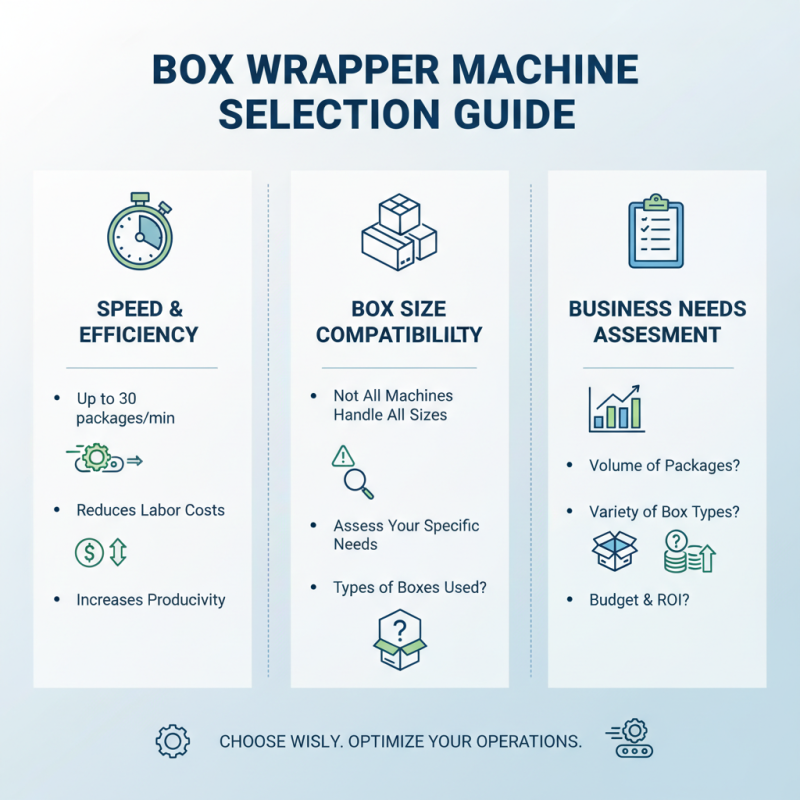

Key Features to Consider When Choosing a Box Wrapper Machine

When selecting a box wrapper machine, consider speed and efficiency. A high-speed machine can wrap up to 30 packages a minute. Efficiency in wrapping reduces labor costs and increases productivity. However, some machines may not handle all box sizes well. It's essential to assess your business's specific needs, including the types of boxes you use.

Another aspect is the machine's ease of operation. User-friendly controls mean less training time for staff. A complex interface can lead to errors and frustrations. Research shows that 50% of packaging errors stem from operator mistakes. Ensure the machine offers a logical workflow for optimal usage and minimal disruptions.

Durability and maintenance are also crucial. Machines made of high-quality materials can prevent frequent breakdowns. According to industry data, 40% of downtime is due to maintenance issues. Choose a model with easy access for repairs. This can save time and money in the long run.

Assessing Production Capacity and Efficiency Needs for Your Business

Choosing the right box wrapper machine involves assessing production capacity and efficiency needs. Understanding your business requirements is critical. A report by Smithers Pira indicates that the global packaging market will reach $2 trillion by 2026. This growth highlights the importance of efficient wrapping solutions.

When evaluating production capacity, consider both current and future needs. For instance, if your business intends to scale, a machine with a higher throughput is essential. Some machines handle up to 30 boxes per minute, while others may only manage 10. This discrepancy can affect your business’s ability to meet orders efficiently.

Efficiency is equally important. Inconsistencies in packaging can lead to waste. A study by Freedonia Group shows that minimizing waste can increase profits by up to 15%. An effective box wrapper machine should not only reduce waste but also ensure consistency in product presentation. Yet, investing in advanced machinery often raises costs. It's a balancing act—choosing technology that aligns with your operational goals while remaining within budget constraints.

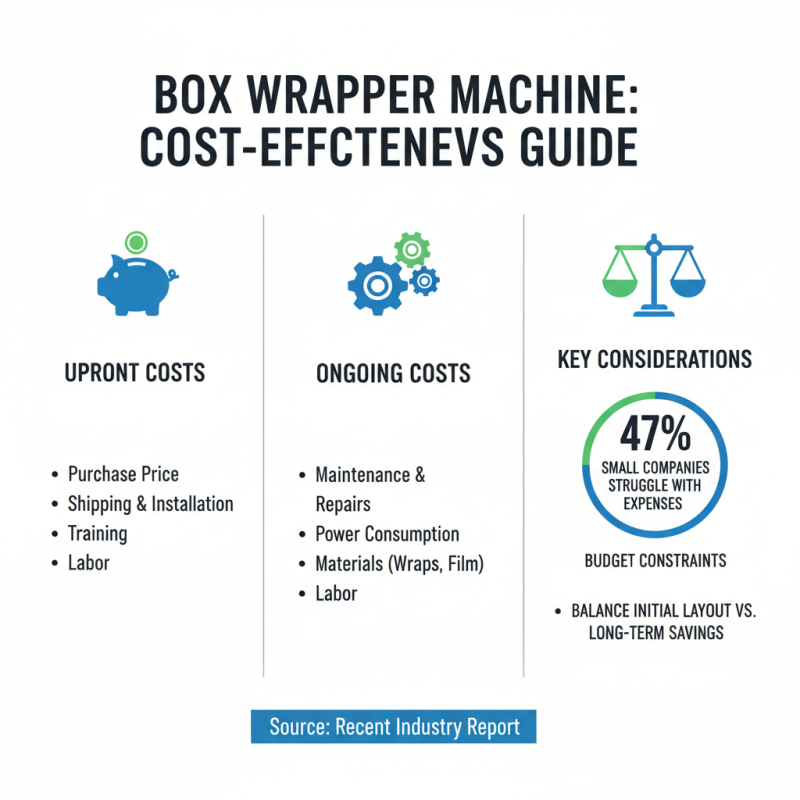

Evaluating Cost-Effectiveness and Budget Constraints for Equipment

When selecting a box wrapper machine, cost-effectiveness is crucial. Businesses must analyze both upfront and ongoing costs. A recent report shows that nearly 47% of small companies struggle with equipment expenses. Budget constraints can limit options, yet it’s essential to find a balance.

Choosing a machine that aligns with budgetary limits often involves exploring less-known models. Sometimes, these can outperform more expensive counterparts. According to industry analysis, manufacturers should assess operational costs, including maintenance and energy consumption. Not all machines offer the same efficiency.

Many businesses overlook the hidden costs, such as training and troubleshooting. A poorly chosen machine may lead to higher operational downtime. Firms should conduct thorough research. Evaluating ROI is essential, especially in a fluctuating market. Ignoring these factors could result in significant losses. Cost-effectiveness is more than just initial price; it is about long-term viability.

Choosing Between Manual, Semi-Automatic, and Fully Automatic Machines

When choosing a box wrapper machine, businesses often face an important decision: manual, semi-automatic, or fully automatic. Each option has its unique benefits and challenges. According to industry reports, manual machines are budget-friendly but may reduce throughput. They work well for small operations or startups, requiring minimal investment while still providing decent flexibility. However, they demand more labor and time. This can become inefficient as demand increases.

Semi-automatic machines offer a middle ground. They automate some processes, boosting productivity while still requiring human oversight. A recent survey found that businesses using semi-automatic machines noted a 30% increase in efficiency. This option is ideal for growing companies needing better output without fully committing resources to automation. Yet, these machines still require regular supervision and maintenance, which can be a challenge.

Fully automatic machines claim the highest efficiency. They reduce labor costs and streamline production immensely. Reports suggest that fully automatic systems can improve productivity by up to 50%. However, the upfront cost can be significant. This may lead to cash flow issues if not properly managed. Amid these choices, consider the demand, budget, and future growth of your business.

Tip: Assess the current and projected output needs before choosing. A poorly matched machine can become a costly mistake.

Tip: Ensure to calculate labor costs versus machine expenses, as this will impact your overall operational efficiency.

2026 Box Wrapper Machine Comparison

This chart compares the costs of different types of box wrapper machines: Manual, Semi-Automatic, and Fully Automatic. As shown, Fully Automatic machines are the most expensive, reflecting their efficiency and advanced technology, while Manual machines offer a cost-effective solution for businesses with lower volume needs.

Related Posts

-

Why You Need a Box Packing Machine for Your Business Efficiency

-

Top 10 Packaging Equipment Innovations You Need to Know About

-

Top Robotic Packing Machines of 2026 What to Expect?

-

2026 Best Small Packaging Machine Options for Efficient Solutions?

-

2026 Top Small Box Packing Machine Innovations and Trends?

-

The Ultimate Guide to Pouching Machines in 2025 for Packaging Solutions