2026 Best Small Packaging Machine Options for Efficient Solutions?

In today's fast-paced world, a small packaging machine plays a crucial role in various industries. These machines are designed to streamline packaging processes. They save space while maximizing efficiency.

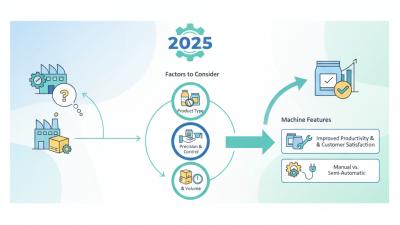

Choosing the right small packaging machine can be challenging. With so many options available, businesses must weigh their needs against features. The best machines often blend speed, reliability, and ease of use. They should enhance productivity without requiring extensive training.

Moreover, not all machines fit every business model. Some may find that initial costs outweigh long-term benefits. It's vital to consider the specific requirements of your products. Investing in the right equipment can lead to significant improvements in workflow and customer satisfaction. Reflecting on these choices will ensure a smarter investment in the future.

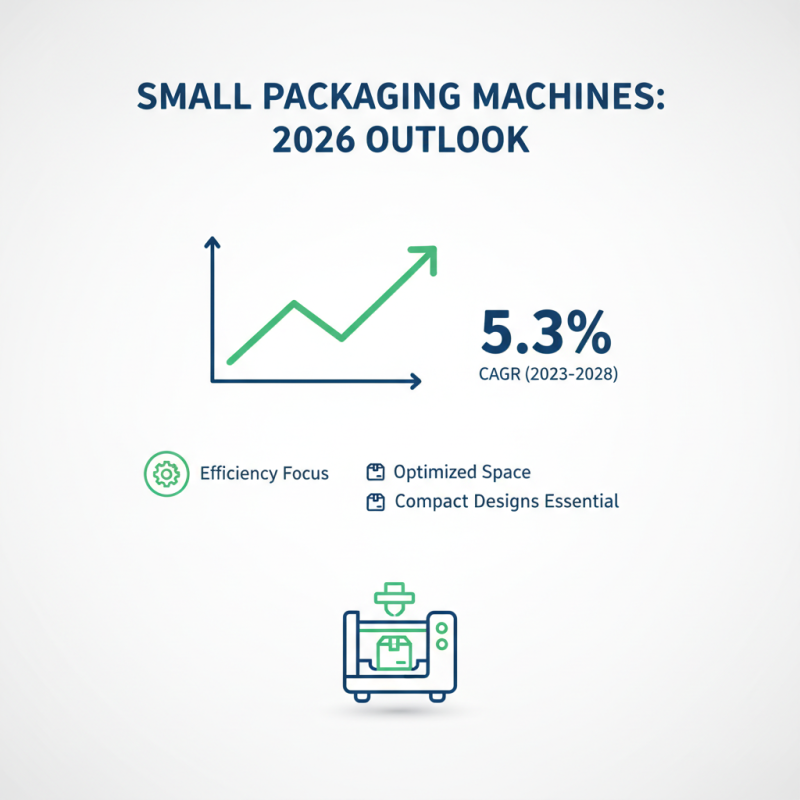

2026 Market Trends in Small Packaging Machine Performance and Efficiency

As we move into 2026, the demand for small packaging machines continues to rise. This trend aligns with the growing focus on efficiency. According to a recent industry report, small packaging machines are projected to see a compound annual growth rate (CAGR) of 5.3% over the next five years. Manufacturers are seeking ways to optimize space while maintaining high throughput. Compact designs are becoming essential.

Efficiency isn’t just about speed. Energy consumption is a significant concern, with reports indicating that energy-efficient models can reduce operating costs by up to 15%. However, not all machines meet these standards. A thorough evaluation is necessary for manufacturers to understand the long-term benefits versus initial investment costs. It's essential to identify areas where improvements can be made, including maintenance procedures and operator training.

The performance gap between various models presents a challenge. Some machines might handle a wide range of products, while others excel only in specific applications. Understanding these nuances can lead to better decision-making. The right choice is not always apparent. Reflecting on real-world applications helps contextualize this complex landscape.

Key Features to Consider When Choosing Small Packaging Machines in 2026

Choosing the right small packaging machine in 2026 requires careful consideration of key features. Efficiency is crucial. A machine should minimize downtime and handle packaging quickly. Look for models with adjustable settings. This flexibility allows you to pack various products effectively. User-friendly interfaces can significantly reduce training time. Simplicity often trumps complexity.

Another important aspect is the machine's versatility. It should accommodate different sizes and shapes of products. Many machines can pack liquids, solids, and powders. This adaptability is beneficial for businesses that offer diverse products. Additionally, consider the machine's maintenance needs. Regular upkeep is essential but can be a hassle. Some designs might complicate this process.

Energy consumption is another factor to reflect on. Machines that use less power can save costs. However, don't overlook output speed. Sometimes, the fastest machines consume more energy. Striking the right balance is key for efficient solutions. It's worth evaluating various options. Finding a machine that meets all your needs can take time and effort. But in the long run, it can significantly enhance productivity.

2026 Best Small Packaging Machine Options

This chart illustrates the efficiency ratings of various small packaging machines based on their performance metrics in 2026. The ratings indicate how effectively each machine can meet packaging demands.

Top Brands and Their Innovative Solutions for Small Packaging Needs

When it comes to small packaging needs, innovation is key. Many brands are pushing boundaries to provide efficient, user-friendly solutions. We often see machines that are compact yet powerful. These machines cater to small businesses seeking to streamline operations. Their designs focus on simplicity while maximizing output. Some models use cutting-edge technology to ensure precise packaging without excessive waste.

Efficiency can sometimes come at a cost. Many options in the market may not be suitable for every business environment. While some machines promise quick results, they may lack the versatility needed for varied products. Additionally, user training is crucial. A machine's effectiveness is only as good as the operator's understanding. Regular maintenance can also be overlooked, leading to breakdowns and downtime.

Exploring available solutions often reveals gaps in what is promised versus actual capabilities. Not all models deliver the expected speed and efficiency. Small businesses should carefully assess their specific needs to avoid mismatches. Although these machines offer innovative solutions, it's essential to think critically about their integration into existing workflows. Balancing function and practicality can be challenging, but it’s a necessary reflection for sustainable growth.

Cost Analysis of Small Packaging Machines: ROI for Businesses in 2026

The demand for small packaging machines is rising. By 2026, the global packaging machinery market is expected to reach $50 billion. Small machines are designed for efficiency. Their compact nature allows flexibility in operations. Businesses can save space and reduce overhead.

Cost analysis is vital when choosing packaging solutions. Initial investments range from $10,000 to $50,000. However, the return on investment (ROI) can be significant. Studies show that businesses could recoup their costs within 12-24 months. Productivity increases by 30% when using automated solutions. Labor costs can decrease by 20% as machines handle repetitive tasks.

Despite these benefits, companies must consider potential downsides. Maintenance costs may increase over time. Training staff to operate new machines can be challenging. It’s essential to evaluate these factors carefully. Balancing cost with efficiency is crucial for sustainable growth. The right solution can enhance productivity while keeping expenses in check.

Case Studies: Success Stories Using Small Packaging Machines in Industry

Small packaging machines are revolutionizing industries worldwide. Companies are discovering innovative ways to meet consumer demands. A recent case study highlights a bakery that increased its output by 30%. They switched from manual packing to an automated small machine. This shift not only improved efficiency but also reduced labor costs. The bakery now meets orders faster and minimizes waste during the packaging process.

Another example comes from a cosmetics brand. They faced challenges with inconsistent packaging quality. After implementing a small packaging solution, their error rate dropped significantly. Customers noticed the improved presentation, leading to positive feedback and increased sales. However, the transition was not entirely smooth. Employees needed time to adjust to the new technology. Training sessions became essential to ensure everyone was on board.

These stories emphasize the benefits of small packaging machines. Yet, they also highlight the need for careful planning. Companies must consider integration with existing workflows. The successes came with their own challenges. Addressing these challenges is key to maximizing efficiency in the long run. Continuous evaluation of processes will help companies stay competitive and responsive to market demands.

2026 Best Small Packaging Machine Options for Efficient Solutions

| Machine Type | Efficiency (%) | Speed (packages/min) | Dimensions (LxWxH cm) | Weight (kg) | Case Study Highlight |

|---|---|---|---|---|---|

| Vertical Bagging | 95 | 30 | 50 x 40 x 150 | 150 | Increased output by 20% in snack packaging. |

| Shrink Wrapper | 90 | 25 | 70 x 50 x 170 | 200 | Reduced material waste by 15% for beverage packs. |

| Carton Sealer | 92 | 20 | 60 x 40 x 140 | 100 | Improved sealing speed led to faster throughput in groceries. |

| Pouch Filler | 88 | 35 | 40 x 30 x 120 | 90 | Streamlined operations led to a 25% productivity boost. |

| Labeling Machine | 87 | 40 | 30 x 30 x 100 | 60 | Achieved consistent labeling accuracy, reducing errors by 10%. |

Related Posts

-

Top 10 Packaging Equipment Innovations You Need to Know About

-

Top Robotic Packing Machines of 2026 What to Expect?

-

2025 Guide: How to Choose the Best Manual Pouch Filling Machine

-

The Ultimate Guide to Pouching Machines in 2025 for Packaging Solutions

-

What is a Pouching Machine? Understanding Its Uses and Benefits

-

Why You Need a Box Packing Machine for Your Business Efficiency