2026 Top Small Box Packing Machine Innovations and Trends?

In the ever-evolving landscape of packaging technology, the small box packing machine stands out as a crucial innovation. Industry expert Dr. Emily Chen, a leading figure in packaging automation, once stated, "Efficiency in small box packing can reshape distribution channels." This highlights the importance of small box packing machines in today’s market.

Recent trends reveal that automation and sustainability are key drivers. Companies are prioritizing machines that maximize efficiency while minimizing waste. The rise of e-commerce amplifies the demand for compact, reliable packing solutions. Small box packing machines must adapt to diverse product sizes and shapes, reflecting the complexity of modern supply chains.

However, as innovations surge, challenges persist. Many packaging facilities struggle with transitioning to new technologies. It raises questions about training and integration. While advancements in small box packing machines promise significant benefits, thoughtful implementation is crucial for success. Balancing innovation with practical application remains a vital focus for the industry, emphasizing the need for continuous improvement.

2026 Advances in Small Box Packing Machine Technology

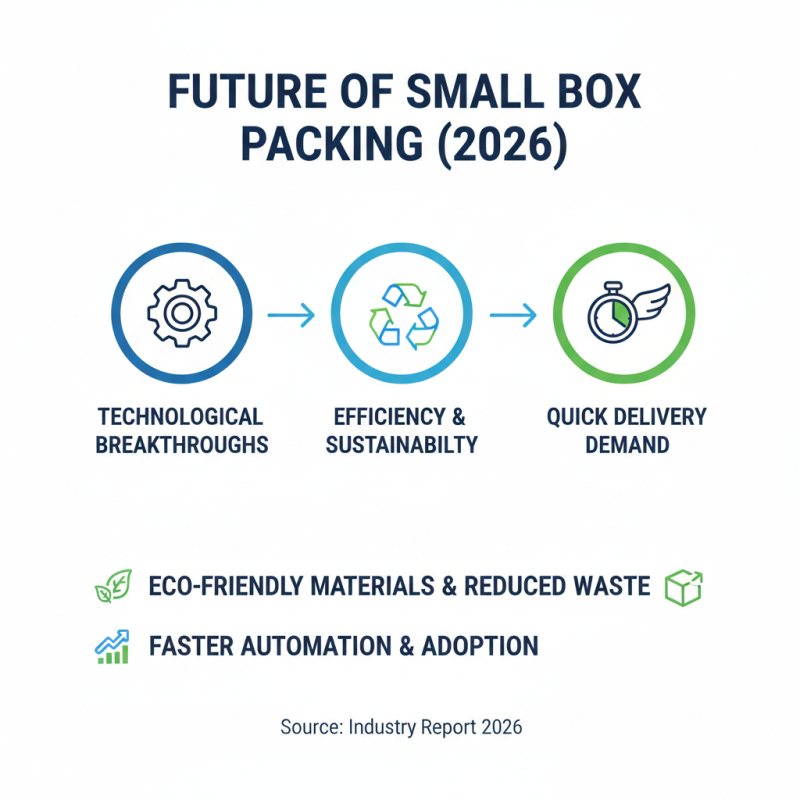

The packing industry is evolving rapidly. In 2026, small box packing machines will showcase remarkable technology breakthroughs. These innovations focus on efficiency and sustainability. Companies are expected to adopt more eco-friendly materials and reduce waste. The growing demand for quick delivery times drives this change.

New automation features are capturing attention. Machines now integrate smart technology to monitor performance. Advanced sensors adjust settings in real-time. This means fewer errors and less downtime. However, not all companies can adapt quickly. The initial investment can be a barrier for small businesses.

Tip: When selecting a packing machine, consider its energy efficiency. It can significantly reduce operating costs over time.

Additionally, user-friendly interfaces are more common. Operators can easily control machines without extensive training. Yet, there may still be issues with software bugs or system crashes. Continuous updates and support are essential.

Tip: Regular maintenance checks are vital for prolonging machine lifespan. Schedule these to avoid unexpected breakdowns and costs.

Key Trends in Automation for Small Box Packing Machines

The landscape of automation in small box packing machines is evolving rapidly. One major trend is the integration of AI technologies. These innovations enhance operational efficiency and accuracy. Machines can now adjust settings autonomously based on input data. This capability reduces human error and speeds up production. However, the reliance on technology means that workers need new skills. Training becomes essential as roles shift.

Another key area is the use of smart sensors. These devices monitor the packing process in real time. They can detect any anomalies or delays. This proactive approach minimizes waste and increases productivity. Yet, implementing such systems can be challenging. There may be compatibility issues with existing equipment. Companies must carefully evaluate their current setup before making changes.

Additionally, sustainability is becoming vital. There is a growing demand for eco-friendly materials in packaging. Many small box packing machines now focus on reducing material waste. However, finding the right balance between sustainability and cost-effectiveness remains difficult. Companies face pressure to innovate while keeping expenses in check. This tension often leads to tough decisions about investment priorities.

Sustainable Materials and Eco-Friendly Innovations in Packing Machines

The packaging industry is shifting toward sustainable materials. Innovations in eco-friendly packing machines are becoming crucial. In fact, a report by Smithers Pira notes that the global market for sustainable packaging is projected to reach $1 trillion by 2027. This growth is encouraging manufacturers to adopt greener practices.

Recyclable and biodegradable materials are gaining traction. Many companies are now using plant-based plastics and recycled paper. For instance, recent studies indicate that 70% of consumers prefer packaging that is environmentally friendly. This demand pushes manufacturers to innovate. However, challenges remain. Not all materials perform well under various conditions. Finding that balance can be tricky.

Adaptations in technology are necessary for these materials. Machine designs must account for different thicknesses and compositions. While some machines excel, others struggle with efficiency and cost. The lack of standardization in eco-friendly materials further complicates the process. Data from the Flexible Packaging Association indicates that these hurdles can slow down innovation. Addressing these issues is essential for progress.

Integrating Smart Technology in Small Box Packing Systems

The integration of smart technology transforms small box packing systems. This evolution not only enhances efficiency but also streamlines operations. Automated systems can adjust settings based on real-time data, resulting in optimized packing processes. Sensors detect box dimensions and weights, ensuring precise packing.

However, challenges exist. Not all machines are fully compatible with existing systems. Some operators may struggle with training. It's crucial to provide adequate support during the transition.

**Tips:** Regularly check equipment updates. This helps in maintaining optimal performance. Additionally, encourage training sessions for all staff. This builds a proficient team ready for technology integration. The future of small box packing looks promising, but careful implementation is key.

2026 Top Small Box Packing Machine Innovations and Trends

Consumer Demand and Customization Trends Impacting Packing Solutions

The demand for customized packaging solutions is rapidly rising among consumers. According to a recent report by Smithers Pira, 70% of consumers prefer brands that offer personalized packaging options. This shift encourages manufacturers to adapt their small box packing machines. Smart technologies and automation are critical in addressing this requirement.

Customization doesn’t just stop at branding. Increasingly, consumers want eco-friendly materials. A study by Freedonia Group indicates that the green packaging market will reach $400 billion by 2025. Businesses need to reflect this in their packaging machines. Features like adjustable settings for different box sizes are becoming essential. Companies face challenges adapting their production lines quickly.

Automation can streamline processes but raises concerns. Not all facilities are ready for high-tech solutions. There is an ongoing skills gap in the workforce. This can impact efficiency and quality. Manufacturers might hesitate to invest in cutting-edge machines without properly trained staff. Revamping training programs can be beneficial yet is often overlooked. Addressing these issues is vital for staying competitive in the evolving landscape.

Related Posts

-

Top Robotic Packing Machines of 2026 What to Expect?

-

Top Benefits of Using a Box Packing Machine in Your Packaging Process

-

What is a Pouching Machine? Understanding Its Uses and Benefits

-

Top 10 Packaging Equipment Innovations You Need to Know About

-

Why You Need a Box Packing Machine for Your Business Efficiency

-

2025 Top Trends in Chemical Packaging Machine Industry You Need to Know