2025 Top Trends in Chemical Packaging Machine Industry You Need to Know

The chemical packaging machine industry is poised for significant evolution by 2025, driven by advancements in technology and a growing emphasis on sustainability. According to a recent report by MarketsandMarkets, the global chemical packaging market is projected to reach USD 50 billion by 2025, with a compound annual growth rate (CAGR) of 5.2% from 2020. This surge highlights the increasing demand for efficient, reliable, and eco-friendly packaging solutions within the sector. As businesses strive to meet regulatory demands and consumer expectations, the role of innovative packaging machinery becomes more critical.

Renowned expert in the field, Dr. Emily Chen, emphasizes the importance of these developments, stating, "The future of chemical packaging machines lies in their ability to integrate smart technology and sustainable practices." This sentiment reflects the industry's focus on enhancing operational efficiency while reducing environmental impact. The incorporation of automation and data analytics is redefining how chemical products are packaged, ensuring safer handling and improved traceability.

As we approach 2025, understanding the top trends in the chemical packaging machine sector is essential for industry stakeholders. From digital transformation to sustainable materials, these trends will shape the future of packaging, enabling companies to adapt to the ever-evolving landscape of consumer needs and regulatory requirements.

Emerging Technologies in Chemical Packaging Machines for 2025

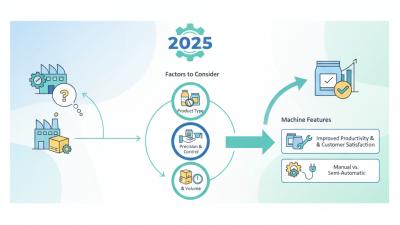

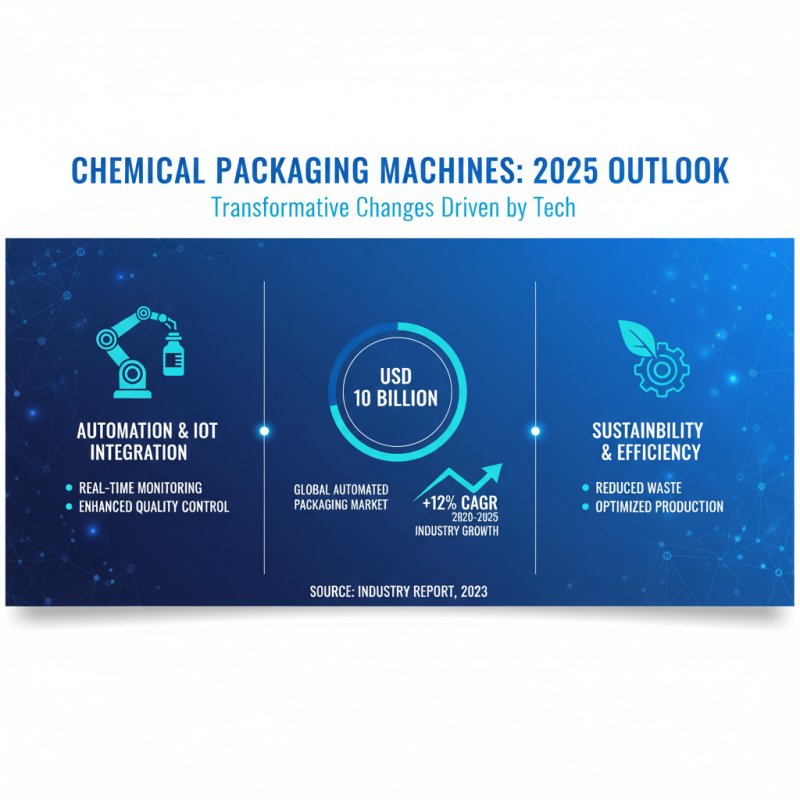

The chemical packaging machine industry is set to experience transformative changes by 2025, driven by emerging technologies. One of the most significant advancements is the integration of automation and IoT (Internet of Things) in packaging systems. These technologies enable real-time monitoring and data collection, allowing manufacturers to optimize production efficiency and enhance quality control. According to a recent industry report, the global market for automated packaging solutions is expected to reach USD 10 billion by 2025, reflecting a CAGR of over 12% from 2020. This shift towards smarter machines not only increases operational efficiency but also reduces waste, supporting sustainability initiatives within the sector.

Another notable trend is the development of advanced materials used in chemical packaging. Innovations such as biodegradable polymers and nanomaterials are gaining traction as companies seek to meet stringent environmental regulations and consumer demand for sustainable products. Research indicates that the market for sustainable packaging in the chemicals industry is projected to grow at a rate of approximately 15% annually, reaching USD 5 billion by 2025. These materials not only offer enhanced protection for chemical products but also contribute to the reduction of carbon footprints, aligning with global efforts to combat climate change. Overall, the convergence of automation and sustainable materials is poised to define the future landscape of the chemical packaging machine industry.

Sustainability Trends Influencing Chemical Packaging Solutions

The chemical packaging machine industry is undergoing a significant transformation driven by sustainability trends. According to a recent report from Smithers Pira, the market for sustainable packaging is projected to grow at a compound annual growth rate (CAGR) of 5.1% globally, reaching approximately $500 billion by 2025. This shift is largely influenced by increasing regulatory pressures and consumer demand for environmentally responsible products. Chemical manufacturers are adopting innovative packaging solutions that not only minimize waste but also utilize biodegradable and recyclable materials, aligning with a broader commitment to environmentally-friendly practices.

A key trend shaping chemical packaging solutions is the move towards circular economy practices. Research from MarketsandMarkets indicates that the demand for recycled packaging materials is set to increase, with the global market reaching $250 billion by 2027. Companies in the chemical sector are now investing heavily in technologies that facilitate the reuse and recycling of materials, thereby reducing their carbon footprint. Additionally, advancements in packaging machine technologies are enabling more efficient production processes, allowing manufacturers to meet sustainability goals without compromising on quality or performance. These changes underscore the industry's responsiveness to sustainability imperatives, positioning it for a future that both recognizes environmental responsibility and meets the evolving needs of consumers.

2025 Top Trends in Chemical Packaging Machine Industry

Automation and Robotics: Revolutionizing the Packaging Process

The chemical packaging machine industry is undergoing a significant transformation, with automation and robotics at the forefront of this evolution. According to a recent report from Allied Market Research, the global market for automated packaging solutions is projected to reach $81 billion by 2027, growing at a compound annual growth rate (CAGR) of 12.5%. This shift towards automation is driven by the increasing demand for efficiency and precision in packaging processes, particularly in the chemical sector where accuracy is paramount to ensure product integrity and safety.

Robotics is playing a crucial role in enhancing the packaging systems by introducing advanced capabilities such as real-time data processing and artificial intelligence. A study by the International Federation of Robotics indicates that the number of industrial robots used in packaging applications is expected to grow significantly, reaching over 1.5 million units by 2025. This rise in robotic integration not only optimizes operational workflows but also minimizes human error, reducing the risks associated with hazardous materials. Furthermore, the adoption of collaborative robots, or cobots, allows for seamless human-robot interaction, enhancing productivity while maintaining worker safety in chemical packaging environments.

The integration of automation and robotics is increasingly becoming a necessity rather than a choice in the chemical packaging machine industry. As companies strive to maintain competitiveness in a rapidly evolving market, leveraging these technologies will be essential for maximizing efficiency, reducing costs, and meeting the stringent regulatory requirements that characterize the packaging of chemicals. The trend signifies a new era in packaging, one that embraces innovation and technological advancement to address the challenges of the future.

2025 Top Trends in Chemical Packaging Machine Industry You Need to Know

| Trend | Description | Impact on Industry | Projected Growth (2023-2025) |

|---|---|---|---|

| Automation in Packaging | Increase in automated systems for faster and more reliable packaging. | Higher efficiency and reduced labor costs. | 15% CAGR |

| Robotics Integration | Implementation of robot arms for precise handling and packaging. | Reduction in errors and increased throughput. | 20% CAGR |

| Sustainability Initiatives | Focus on eco-friendly materials and reducing waste in packaging processes. | Positive public perception and compliance with regulations. | 10% CAGR |

| Smart Packaging Technology | Use of IoT and sensors in packaging for monitoring and tracking. | Improved supply chain efficiency and product safety. | 25% CAGR |

| Customized Packaging Solutions | Tailored packaging options to meet specific customer needs. | Higher customer satisfaction and loyalty. | 18% CAGR |

Cost-Effective Innovations in Chemical Packaging Machinery

In recent years, the chemical packaging machinery industry has undergone significant transformations geared towards cost-effective innovations. One of the foremost trends is the integration of advanced automation technologies, which streamline operations and reduce labor costs. By employing automated systems, manufacturers can enhance efficiency while minimizing errors that often result in waste. This shift not only boosts productivity but also contributes to sustainable practices by lowering resource consumption in the packaging process.

Another promising development is the use of eco-friendly materials in packaging machinery. As companies strive to meet increasing regulatory standards and consumer demand for sustainability, machinery that accommodates biodegradable and recyclable materials is gaining traction. These innovations help manufacturers reduce their carbon footprint and appeal to environmentally conscious consumers. Additionally, adopting energy-efficient technologies in machinery design further lowers operational costs, making it a win-win situation for businesses aiming to improve both their financial and environmental performance.

Regulatory Changes Impacting the Chemical Packaging Industry in 2025

As we move closer to 2025, the chemical packaging industry is poised for significant transformations influenced by evolving regulatory frameworks. Regulatory changes are expected to prioritize sustainability and safety, prompting manufacturers to adopt environmentally friendly materials and innovative designs. These regulations will not only affect the materials used in packaging but also the processes manufacturers need to follow to ensure compliance. Companies must be prepared to adjust their operations to align with new standards, which will ultimately impact product lifecycle management.

Tips:

1. Stay informed about upcoming regulations by subscribing to industry newsletters or joining professional associations. This will help you anticipate changes and adapt your strategies effectively.

2. Invest in training your staff to understand new compliance requirements and best practices, ensuring that your team is equipped to handle the shifts in regulatory expectations.

Additionally, regulatory bodies are likely to focus on reducing single-use plastics and enhancing recycling practices. This shift will encourage investment in advanced packaging technologies that not only meet regulatory demands but also appeal to consumers’ growing preference for sustainable products. Companies that proactively innovate and adapt will not only meet compliance but also position themselves as leaders in a rapidly changing market.

Tips:

3. Explore partnerships with suppliers who specialize in sustainable packaging solutions to streamline your transition to compliant, eco-friendly options. This collaborative approach can enhance product integrity while satisfying regulatory criteria.