2025 Guide: How to Choose the Best Manual Pouch Filling Machine

In the rapidly evolving landscape of packaging technology, the manual pouch filling machine stands out as an essential tool for businesses looking to enhance efficiency and precision. With the increasing demand for flexible and customizable packaging solutions, understanding how to choose the best manual pouch filling machine has become critical for manufacturers and entrepreneurs alike. This guide for 2025 will navigate you through the various features and factors to consider when selecting the ideal machine that meets your specific operational needs.

As businesses strive to adapt to changing market demands, the versatility of manual pouch filling machines offers significant advantages. These machines not only allow for greater control over the filling process but also support a wide range of products, from food items to pharmaceuticals. An informed decision is vital, as the right manual pouch filling machine can lead to improved productivity, reduced waste, and ultimately, increased customer satisfaction. Whether you are a startup aiming to establish your packaging line or an established company seeking to upgrade your equipment, this guide will provide you with the necessary insights to make a well-rounded decision.

Understanding Manual Pouch Filling Machines: An Overview

Manual pouch filling machines are essential tools in various packaging processes, primarily used for filling pouches with a wide range of products, including powders, granules, and liquids. These machines are designed to provide a simple yet effective solution for businesses that require flexibility and mobility in their packaging operations. Understanding the components and functionalities of manual pouch filling machines is crucial for selecting the right equipment for your needs.

The overview of manual pouch filling machines reveals that they typically consist of a filling nozzle, a support frame, and controls that allow operators to manage the filling process efficiently. One of the significant advantages of manual machines is their cost-effectiveness, as they generally require less investment compared to automated systems. Moreover, these machines are particularly beneficial for small-scale operations or businesses with lower production volumes since they can be easily adjusted to accommodate different pouch sizes and product types. By focusing on these essential features, companies can make informed decisions that align with their operational requirements and budget constraints.

Key Features to Consider When Selecting a Manual Pouch Filling Machine

When selecting a manual pouch filling machine, it's vital to consider several key features that can significantly impact your production efficiency and product quality. First and foremost, the machine's filling accuracy is paramount. Industry reports suggest that a filling accuracy of ±1% is ideal for most operations, ensuring that every pouch is filled to the desired specification. Additionally, the machine's versatility allows it to handle a variety of pouch sizes and materials, making it a valuable asset for businesses with diverse packaging needs.

Another essential feature to review is the ease of use and maintenance of the machine. A user-friendly interface can minimize training time for new operators, while quick-change parts make it easier to switch between different pouch types. Reports show that facilities that implement intuitive designs can reduce downtime by as much as 20%, directly impacting production capacity.

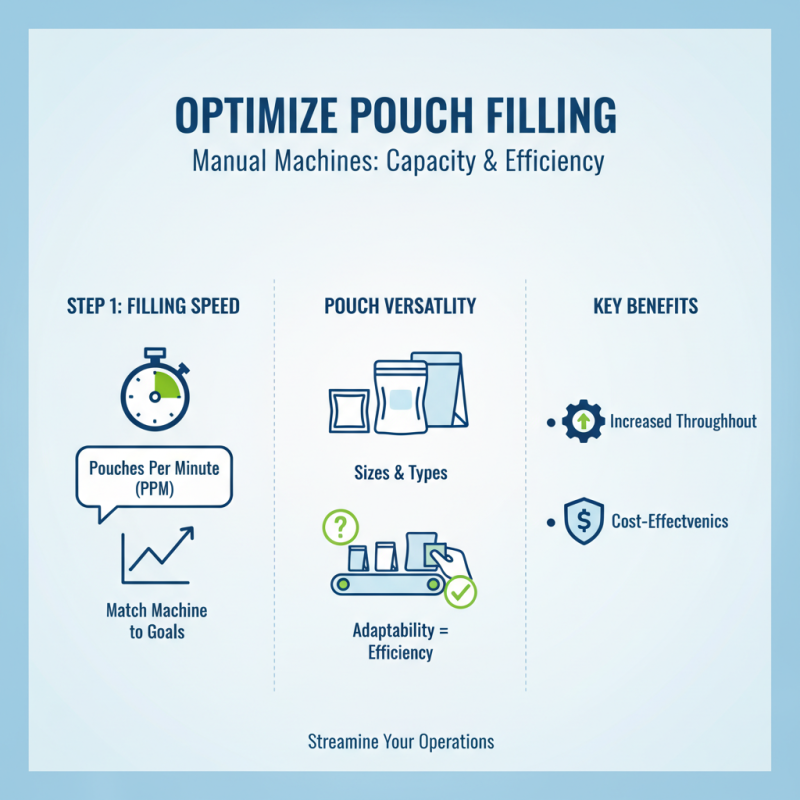

Assessing Production Capacity and Efficiency of Filling Machines

When selecting a manual pouch filling machine, assessing production capacity and efficiency is crucial for optimizing operational workflows. The first step in this assessment involves evaluating the speed at which the machine can fill pouches. This is typically measured in pouches per minute, and understanding this metric helps you align machine capabilities with your production goals. Consideration should also be given to the machine's ability to handle various pouch sizes and types, which can impact the overall efficiency of the filling process.

Additionally, the efficiency of a manual pouch filling machine can depend on its ease of use and maintenance. Machines that require less frequent calibration or adjustment can significantly reduce downtime and improve productivity. User-friendly designs that allow for quick changeovers between different pouch formats can further enhance operational throughput. An efficient filling process should minimize product waste and ensure consistent fill levels, which not only saves costs but also enhances product quality. By focusing on these aspects, you can make an informed choice that aligns with your production needs and improves overall efficiency in your packaging operations.

Exploring Different Types of Pouches Compatible with Filling Machines

When selecting a manual pouch filling machine, it's essential to consider the various types of pouches compatible with these filling systems. Different pouch styles serve distinct purposes, which can impact efficiency and overall production effectiveness. Common types of pouches include flat pouches, stand-up pouches, and zipper pouches. Each type has its unique characteristics and applications; for instance, stand-up pouches are ideal for products that benefit from shelf presence, while flat pouches are often used for single servings and compact designs.

Additionally, the materials used in pouches can significantly influence the filling process. Pouches made from plastic, foil, or biodegradable materials each require different handling and sealing approaches. Plastic pouches are versatile and commonly used across various industries due to their durability and lightweight nature. In contrast, foil pouches provide excellent barrier properties, making them suitable for products sensitive to light and oxygen.

Understanding these differences will help in choosing a manual pouch filling machine that not only fits the pouch type but also enhances operational efficiency, ensuring that the filling process aligns with the specific requirements of the packaged products.

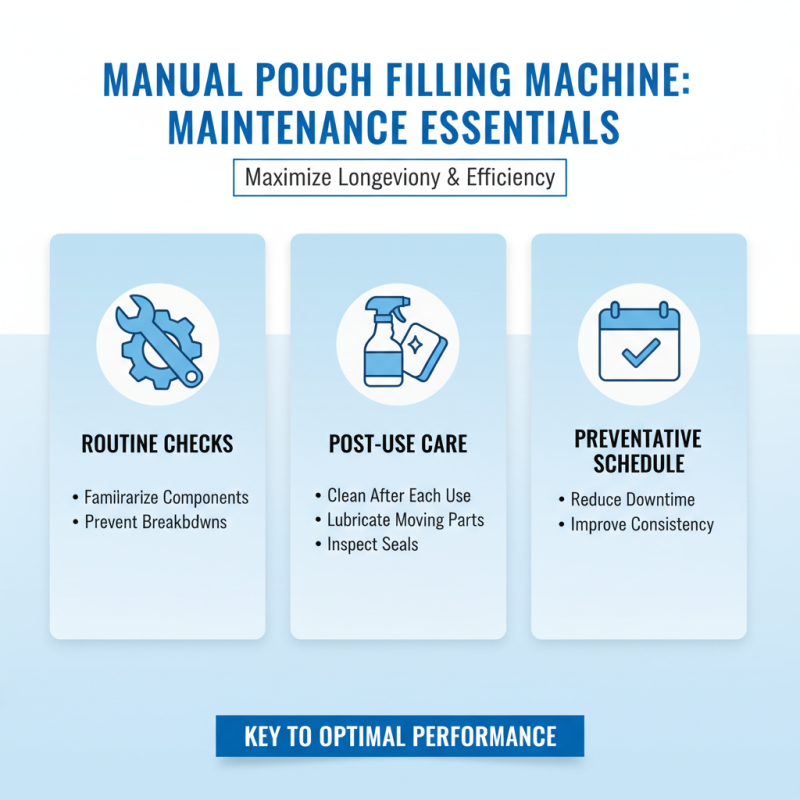

Maintenance and Support for Manual Pouch Filling Machines: What to Know

When selecting a manual pouch filling machine, understanding maintenance and support options is crucial. Regular maintenance plays a vital role in ensuring the longevity and efficiency of the machine. Operators should familiarize themselves with the machine’s components, as routine checks can prevent unexpected breakdowns. Cleaning the machine after each use, lubricating moving parts, and inspecting seals for wear are essential steps in maintaining optimal performance. By adhering to a preventive maintenance schedule, users can significantly reduce downtime and improve the consistency of their pouch filling operations.

In addition to maintenance, having access to reliable support is essential for any operator of manual pouch filling machines. It's important to understand the type of support offered by the manufacturer or supplier. This includes availability of technical assistance, replacement parts, and user training. A responsive support team can help troubleshoot issues swiftly, minimizing disruption in production. Furthermore, investing in user training can empower operators to handle the machine efficiently, ensuring that they are aware of best practices for operation and maintenance. With proper care and support, a manual pouch filling machine can enhance productivity and deliver high-quality results over its operational lifespan.